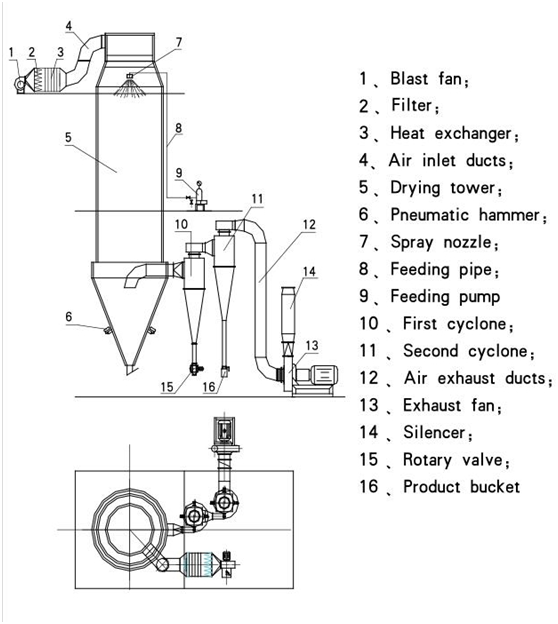

The heated clean air enters into the drying tower, in the drying tower, use two fluids (or three fluids) sprayer to atomize the water or solvent in the liquid into fine mist. The mist contacts hot air, and the water in material liquid will be evaporated immediately. The air will be exhausted by exhaust fan, and the product will be collected at the bottom of the drying tower and dust collector.

It is particularly applicable for the viscous, paste and paste-like materials, the performances are perfect, and it is not be replaceable by the other machines. A lot of varieties for trial machines, wide applications for low temperature drying. Simple spray structure, easy maintenance and low running cost.

- Food Industry: whole milk powder, skimmed milk powder, cocoa milk powder, milk substitute, egg white (yolk), etc. armpit prion, Oats, chicken juice, instant tea, seasoning meat, protein, soybean, peanut protein, protein thydrolyzate. Corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, pumpkin powder, instant coffee, and non-dairy creamer etc.

- Pharmaceutical products: Chinese traditional medicine extract (herb extract), medicine colloid, yeast, vitamins, antibiotics, amylase, lipase, etc.

- Plastics resin: AB, ABS emulsion, urea-formaldehyde resin, phenolic resin, dense plastic (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc.

- Detergent: advanced washing powder, normal washing powder, soap powder, soda powder, emulsifiers, brighteners, phosphoric acid agents.

- Chemical Industry: Sodium fluoride (potassium), alkaline dyestuff and pigment, dye intermediates, Mn3O4, formic silica acid, catalyst, sulfuric acid agent, amino acids, silica, etc..

- Ceramic: aluminum oxide, ceramic tile material, magnesium oxide, talc, etc.

Specifications | QPG-5 | QPG-25 | QPG-50 | QPG-100 | QPG-150 | QPG-200 |

Air Inlet temperature | ||||||

Air exhaust temperature | 60-120 ° C (depend on the product to be dried, and URS) | |||||

Nominal water evaporationcapacity (Kg / h) | 5 | 25 | 50 | 100 | 150 | 200 |

Heating method | High-pressure steam, or steam + electricity, or any kinds of fuel (diesel, natural gas, liquefiedpetroleum gas or coal, etc.), or solid fuel (any combustible material). Please specify. | |||||

Compressed air pressure (MPa) | 0.4 | 0.6 | 0.7 | |||

Compressed air consumption(m³/min) | 0.9 | 0.9 | 1.1 | 1.5 | 2.7 | 3.4 |

Heat required (KCal/h) | 1 | 5 | 10 | 20 | 30 | 40 |

Power of Fan (kw) | 0.75 | 4 | 7.5 | 11 | 15 | 18.5 |

Yield of product | 95-99.5%, depend on the properties of the product and configurations | |||||

Specifications | QPG-500 | QPG-1000 | QPG-1500 | QPG-2000 | QPG-5000 | QPG-10000 |

Inlet air temperature | 140-550 ° C (depend on the product to be dried, and URS) | |||||

Air exhaust temperature | 60-120 ° C (depend on the product to be dried, and URS) | |||||

Nominal amount of water evaporation(Kg/hour) | 500 | 1000 | 1500 | 2000 | 5000 | 10000 |

Heating method | High-pressure steam, or steam + electricity, or any kinds of fuel (diesel, natural gas, liquefiedpetroleum gas or coal, etc.), or solid fuel (any combustible material). Please specify. | |||||

Compressed air pressure (MPa) | 0.7 | 0.7 | 0.7 | 0.7 | ||

Compressed air consumption(m³/min) | 7.5 | 1.4 | 2.0 | 2.5 | 5.0 | 9.0 |

Calorie requirement (KCal/h) | 100 | 200 | 300 | 400 | 500 | 1000 |

Fan power (kw) | 45 | 90 | 125 | 160 | 380 | 700 |

Yield of product | 95-99.5%, depend on the properties of the product and configurations | |||||

Note:These parameters for reference only and will be changed as per URS.