Coffee is mainly divided into three varieties: Arabic, Robusta and Liberica. Now in the market, Arabic and Robusta is more popular Arabic is planted at the attitude of 1000-1800m, while the altitude of Robusta is generally relatively lower, so the caffeine content of Arabica is relatively lower. In general, an Arabica coffee tree can produce about 0.3-0.4kg instant coffee, a Robusta coffee tree produces more.

Coffee tree is tropical evergreen perennial shrub, grows up to three to five years old will have fruit, open white clustered flowers, similar to tea flower of shape and smell, flowering only a few days, end of green coffee beans, then change into yellow, red and darker color. Fruit maturity is usually from 6 to 10 months. In each piece of fruit,there are two coffee beans, ripen coffee bean like red cherry,so it is called coffee Cherry.

After harvest of coffee beans, by dry and wet method to peel, dry, shell. Sometimes it is necessary to polish the coffee beans then enter the production line.

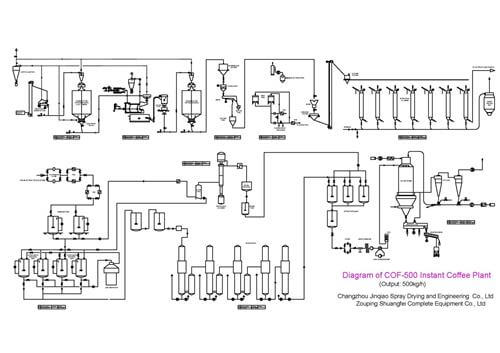

Instant coffee equipment includes pretreatment, roasting, extraction, separation, aroma recovery, concentration, drying, and the agglomerator or subsystems as per client's requirements, such as packaging system and CIP system, etc.

i. Pre-treatment

Before process the coffee beans purchased from the market, it is necessary to do screen separation, dedusting and then store the beans for roasting. After separation, coffee beans are separated into different grades, different roasting parameters works for different grades of beans, so have the best roasting results.

ii. Roasting

A small coffee bean contains over 2000 substances, up to now we know around 700 kinds.

The roasting process is carbonation of the active ingredients contained in coffee beans, generate coffee oil, and produce high-quality coffee withconsistent style.

iii. Extraction

Roasted coffee has special aroma withstand relatively low temperature. Traditional extraction process loses the coffee aroma, so the coffee's aroma is not enough. In a lot of process, they add food additives to improve the taste of coffee. Coffee lost its own attractive as nature's drink.

Our extraction process keeps the maximum nature aroma. The extracted aroma will be separated by flash separator and stored separately.

The extract section normally included six to eight extraction columns. Each extraction column is designed to withstand 25bar pressure, easy residue-discharging device and controlled by advanced technology.

Our special design increases the solid contents of the extract from 12-13% to 18-22%, so to reduce the investment of downstream process and decrease energy consumption.

iv. Separation

During process the coffee beans, it is inevitable have some ash. And it is easy to mix some fibrous material in the coffee extract. In order to improve the quality and ensure there's no insoluble materials when the customers solve instant coffee in water. We suggest a separator after separation.

v. Concentration

Concentration has two purposes: increase the concentrate of coffee extract, so to reduce the investment of drying section before drying process(spray dryer or vacuum freeze dryer); decrease the water content of extract, so save the energy.

In some processes, concentrated coffee extract or just coffee extract are sold in the market directly to produce tinned coffee, bottled coffee, and mixed drinks, or do some further process to make coffee biscuits, coffee candy or other coffee snack and so on.

vi. Drying

There are two kinds of drying methods for Coffee: freeze drying and spray drying.

i)Freeze Diying

Freeze drying section consists of cooling, foaming and pre-freezing section, freezing section, granulation section, drying cart loading section and drying section, as well as fines return section. Freeze drying maximally keep the coffee's flavor and color. The color, flavor, bulk density and solubility of final product meet the market demands, so the price is much higher in the market.

But the investment, running cost of the freeze-drying plant are very high, and the fines return rate is also high, freeze-dryer is not a popular drying process.

ii) Spray Drying

With many years of research, we have developed special technologies and designs to meet different requirements of the product, such as product size, bulk density and flowability etc. In traditional coffee spray dryer, fluidized bed is generally a combination of external cooling dry. The traditional coffee spray dryers have external fluid beds for drying and cooling. Our design has inner fluidized bed to make the product meets the requirements of moisture contents and packing temperature.

The particle of final product from spray dryer is normally within the range of 100-350 micron, varies as per the configuration of the plant, processing parameters, and scale of the plant etc.

Our special design also increased the product collection rate. As per the parameters from our customers, the highest product collection rate is around 99.7%.

The factors that influences the final product, not only the final drying section, but also the fore process. To have the best product, it is necessary to coordinate the entire process.

vii. Agglomeration / granulation

To meet the market requirements of big particles and no dust, we also supply agglomeration equipment, which can make the small particles from spray dryer into big particles. Depends on requirements of different customers, the agglomerated particles are normally within the range of 1500-3500 microns.

viii.Automatic control

ThereYe different control levels for the plant, such as push button type, semi-automatic control and automatic control. Now the most popular one is semi-automatic control system, which investment is low and operators, knowledge requirements are normal, and the relative parameters could be recorded.

Full automatic control system, sometimes includes SCADA system requires the least operators, but the operators' knowledge requirements are high. It will check and record all necessary production parameters, so it is easy to trace the quality of the product.

No mater semi-auto or automatic control system, we have adopted standard components and modules for easy maintenance and upkeep of the customers. And the operators could set different parameters for different recipes, so to produce different products to meet the requirements of different customers and different markets.

ix. WIP System

Cleaning of food processing equipment is a time consuming work, which occupies a lot of production time, our company supply Washing In Place with different configurations for customers option.

Specification | COF-50 | COF-100 | COF-300 | COF-500 | COF-1000 | COF-1500 |

Green bean processing capacity (Kg/H) | 110-150 | 220-300 | 660-900 | 1,100-1,500 | 2,200-3,000 | 3,300-4,500 |

Nominal Output (Kg/H) | 50 | 100 | 300 | 500 | 1,000 | 1,500 |

Annual Ouput (8000H/Y) (Ton/Y) | 400 | 800 | 2,400 | 4,000 | 8,000 | 12,000 |

Area required (m2) | 600-700 | 700-800 | 1,100-1,200 | 1,300-1,400 | 2,100-2,250 | 2,700-2,900 |

Product collection rate | 99-99.7% (Depend on the specification, configuration and URS) | |||||

Final moisture contents (%) | < 3%(Depends on URS) | |||||

Bulk density of product (Kg/L) | 0.18-0.35 (Depend on the configuration, specification and processing parameters) | |||||

Average particle size (meshes) | 100-350 (Depend on the configuration, specification and processing parameters) | |||||

Discharge temperature (°C) | 35-45 °(Depends on configuration and URS) | |||||

Fuel | Suggest natural gas for drying section (please specify if not), steam boiler works with any fuel, including combustible waste material, such as extracted coffee beans mixed with coal etc) | |||||

Note:These parameters for reference only and will be changed as per URS.